Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

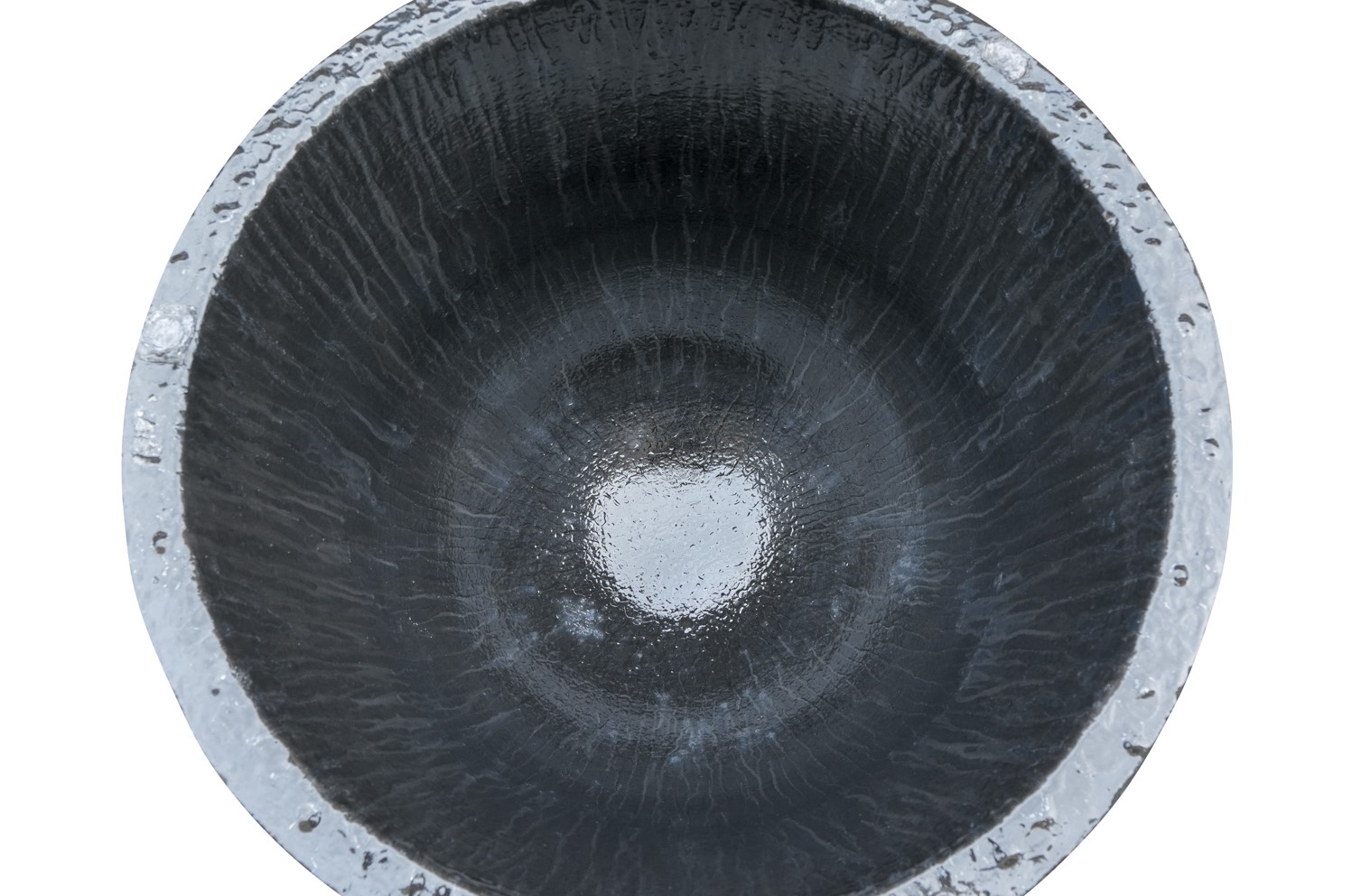

Metala Hoʻoheheʻe Crucible Aluminum hehee no ka hoolei ana

NA HI'O HUA

Heheʻe wikiwiki

Hoʻonui ka graphite thermal conductivity kiʻekiʻe i ka hana wela ma 30%, e hōʻemi nui ana i ka manawa hoʻoheheʻe.

ʻOi aku ka pale ʻana i ka haʻalulu wela

ʻO ka ʻenehana hoʻopaʻa ʻia ʻo Resin ke kū i ka hoʻomehana wikiwiki a me ka hoʻoluʻu ʻana, e ʻae ana i ka hoʻopiʻi pololei ʻana me ka haki ʻole.

Kūʻokoʻa Paʻa

ʻO ka ikaika mechanical kiʻekiʻe e kū'ē i ka hopena kino a me ka hoʻoheheʻe kemika no ka lōʻihi o ke ola lawelawe.

HANA HANA

| graphite / % | 41.49 |

| SiC / % | 45.16 |

| B/C / % | 4.85 |

| Al₂O₃ / % | 8.50 |

| ʻAno nui / g·cm⁻³ | 2.20 |

| ʻIke ʻia ka porosity / % | 10.8 |

| Ka ikaika ʻohi/MPa (25 ℃) | 28.4 |

| Modulus o ka nahae/ MPa (25 ℃) | 9.5 |

| Ka wela pale ahi/ ℃ | >1680 |

| Kū'ē haʻalulu wela / Manawa | 100 |

| No | Hoʻohālike | H | OD | BD |

| RA100 | 100# | 380 | 330 | 205 |

| RA200H400 | 180# | 400 | 400 | 230 |

| RA200 | 200# | 450 | 410 | 230 |

| RA300 | 300# | 450 | 450 | 230 |

| RA350 | 349# | 590 | 460 | 230 |

| RA350H510 | 345# | 510 | 460 | 230 |

| RA400 | 400# | 600 | 530 | 310 |

| RA500 | 500# | 660 | 530 | 310 |

| RA600 | 501# | 700 | 530 | 310 |

| RA800 | 650# | 800 | 570 | 330 |

| RR351 | 351# | 650 | 420 | 230 |

KA HANA

1. Hoʻoponopono pololei

ʻO ka graphite maʻemaʻe kiʻekiʻe + carbide silicon premium + mea hoʻopaʻa paʻa waiwai.

.

2.Isostatic Pressing

ʻO ka nui a hiki i ka 2.2g/cm³ | ʻO ka mānoanoa o ka pā ± 0.3m

.

3.High-Temperature Sintering

ʻO ka recrystallization ʻāpana SiC e hana ana i ka ʻōnaehana pūnaewele 3D

.

5.ʻO ka nānā ʻana i ka maikaʻi

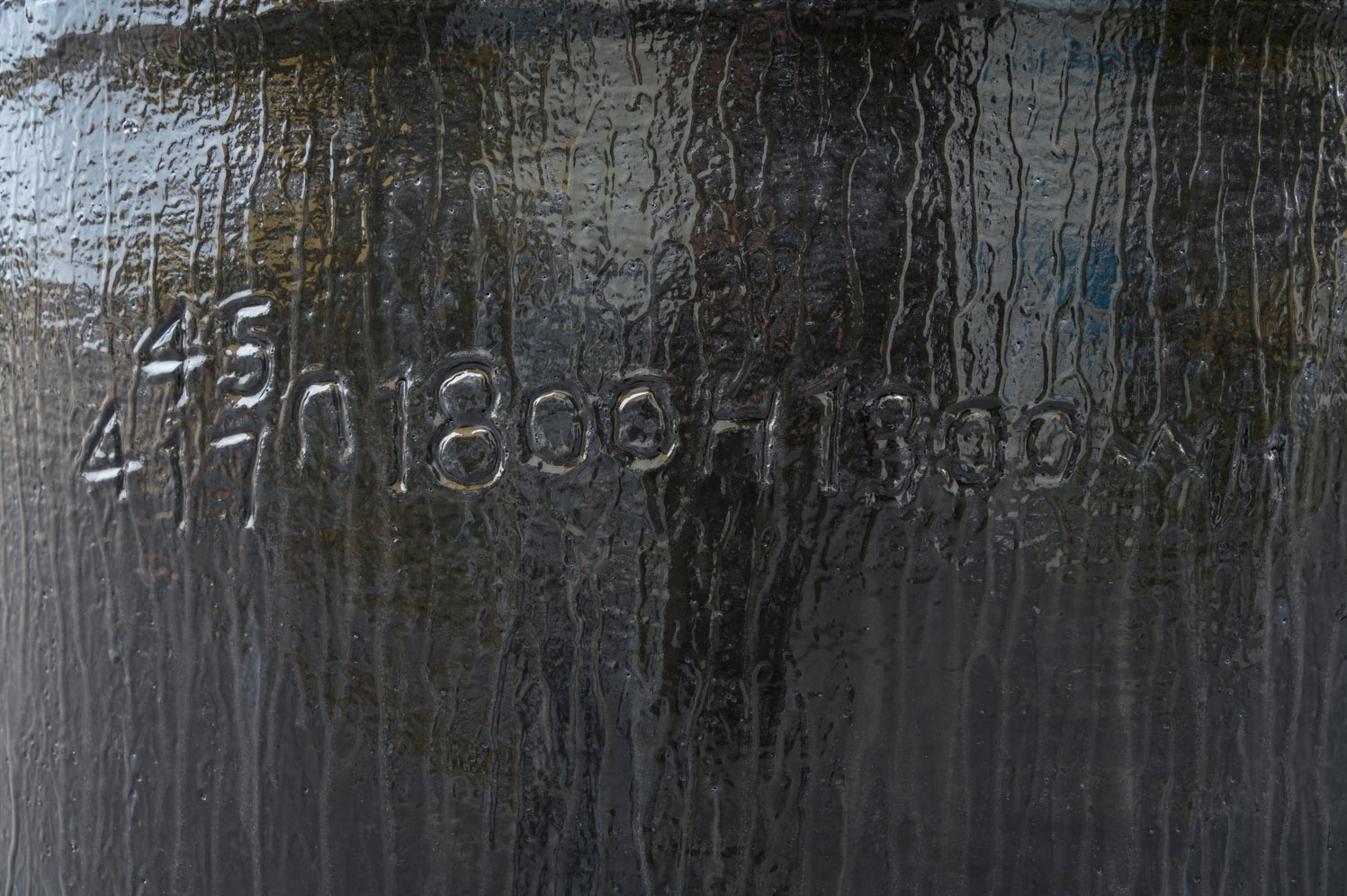

Helu hoʻopaʻa inoa kūʻokoʻa no ka hiki ʻana o ke ola holoʻokoʻa

.

4. Hoʻonui i ka ʻili

ʻO ka uhi anti-oxidation → 3 × hoʻomaikaʻi i ka pale ʻana i ka corrosion

.

6.Hoʻopili palekana

ʻO ka papa haʻihaʻi haʻihaʻi + ʻaʻa wai + ka pahu hoʻoikaika ʻia

.

HOOLAHA HANA

He kūpono no ka hapa nui o nā metala non-ferrous

Aluminum hehee

Ke keleawe hehee

Hehe gula

No ke aha e koho ai iā mākou

FAQ

Q1: Hiki i ka Crucible Cover ke hoʻemi i nā kumukūʻai ikehu?

A: ʻOiaʻiʻo! Hoʻemi ia i ka nalowale o ka wela, ʻoki i ka hoʻohana ʻana i ka ikehu a hiki i 30%.

Q2: He aha nā kapuahi i kūpono?

A: He mea maʻalahi - kūpono no ka hoʻokomo ʻana, ke kinoea, a me nā umu uila.

Q3: He palekana ka graphite silicon carbide no nā wela kiʻekiʻe?

A: ʻAe. ʻO kona kūpaʻa wela a me ke kemika e kūpono ia no nā kūlana koʻikoʻi.

Q4: Pehea e pale ai i ka crucible cracking?

Mai hoʻouka i ka mea anuanu i loko o kahi kīʻaha wela (max ΔT <400°C).

Ka helu hoʻoluʻu ma hope o ka hoʻoheheʻe ʻana <200°C / hola.

E hoʻohana i nā ʻōpala crucible i hoʻolaʻa ʻia (e pale i ka hopena mechanical).

Q5: Pehea e pale aku ai i ka haki ʻana o ka crucible?

Mai hoʻouka i ka mea anuanu i loko o kahi kīʻaha wela (max ΔT <400°C).

Ka helu hoʻoluʻu ma hope o ka hoʻoheheʻe ʻana <200°C / hola.

E hoʻohana i nā ʻōpala crucible i hoʻolaʻa ʻia (e pale i ka hopena mechanical).

Q6: He aha ka helu kauoha liʻiliʻi (MOQ)?

Nā Hoʻohālike Maʻamau: 1 ʻāpana (loaʻa nā laʻana).

Nā Hoʻolālā Kuʻuna: 10 mau ʻāpana (pono CAD kiʻi).

Q7: Ua hōʻoia ʻia ʻoe e kekahi hui ʻoihana?

Hāʻawi kā mākou hui i kahi kōpili hoihoi o nā palapala hōʻoia a me nā pili i loko o ka ʻoihana. Loaʻa kēia i kā mākou palapala hōʻoia ISO 9001, e hōʻike ana i kā mākou kūpaʻa i ka hoʻokele maikaʻi, a me kā mākou lālā i kekahi mau hui ʻoihana hanohano.

Q8: He aha ka graphite carbon crucible?

ʻO ka graphite carbon crucible kahi kīʻaha i hoʻolālā ʻia me ka waiwai conductivity thermal kiʻekiʻe a me ke kaʻina hana hoʻoheheʻe isostatic kiʻekiʻe, nona ka hiki ke hoʻomehana maikaʻi, ka ʻano like ʻole a me ka paʻa a me ka hoʻokele wela wikiwiki.

Q9: He aha inā makemake wau i kahi mau kīʻaha carbide silicon a ʻaʻole i ka nui?

Hiki iā mākou ke hoʻokō i nā kauoha o kēlā me kēia nui no nā crucibles carbide silika.

Hana Hana #1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Hana Hana #2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Nā hōʻike

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, and feugiat tortor porttitor vel. Nullam id scelerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis.

- Jane Doe

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, and feugiat tortor porttitor vel. Nullam id scelerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis. Nam luctus mauris elit, sed suscipit nunc ullamcorper ut.

- John Doe