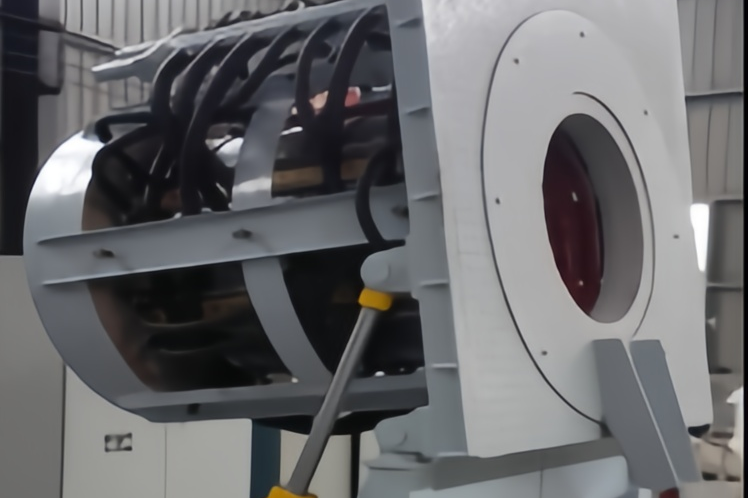

ʻO ka pahu hoʻoheheʻe gula a me ke kala

NA HI'O HUA

ʻOi aku ka maikaʻi o ka wela wela

ʻO ka hui kūʻokoʻa o ka silicon carbide a me ka graphite e hōʻoia i ka hoʻomehana wikiwiki a me ke ʻano like ʻole, e ʻoki nui ana i ka manawa hoʻoheheʻe.

Kūleʻa wela loa

ʻO ka hui kūʻokoʻa o ka silicon carbide a me ka graphite e hōʻoia i ka hoʻomehana wikiwiki a me ke ʻano like ʻole, e ʻoki nui ana i ka manawa hoʻoheheʻe.

Paʻa Paʻa Paʻa

ʻO ka hui kūʻokoʻa o ka silicon carbide a me ka graphite e hōʻoia i ka hoʻomehana wikiwiki a me ke ʻano like ʻole, e ʻoki nui ana i ka manawa hoʻoheheʻe.

HANA HANA

| graphite / % | 41.49 |

| SiC / % | 45.16 |

| B/C / % | 4.85 |

| Al₂O₃ / % | 8.50 |

| ʻAno nui / g·cm⁻³ | 2.20 |

| ʻIke ʻia ka porosity / % | 10.8 |

| Ka ikaika ʻohi/MPa (25 ℃) | 28.4 |

| Modulus o ka nahae/ MPa (25 ℃) | 9.5 |

| Ka wela pale ahi/ ℃ | >1680 |

| Kū'ē haʻalulu wela / Manawa | 100 |

| ʻAno/ʻano | A (mm) | B (mm) | C (mm) | D (mm) | E x F max (mm) | G x H (mm) |

|---|---|---|---|---|---|---|

| A | 650 | 255 | 200 | 200 | 200x255 | Ma ke noi |

| A | 1050 | 440 | 360 | 170 | 380x440 | Ma ke noi |

| B | 1050 | 440 | 360 | 220 | ⌀380 | Ma ke noi |

| B | 1050 | 440 | 360 | 245 | ⌀440 | Ma ke noi |

| A | 1500 | 520 | 430 | 240 | 400x520 | Ma ke noi |

| B | 1500 | 520 | 430 | 240 | ⌀400 | Ma ke noi |

KA HANA

1. Hoʻoponopono pololei

ʻO ka graphite maʻemaʻe kiʻekiʻe + carbide silicon premium + mea hoʻopaʻa paʻa waiwai.

.

2.Isostatic Pressing

ʻO ka nui a hiki i ka 2.2g/cm³ | ʻO ka mānoanoa o ka pā ± 0.3m

.

3.High-Temperature Sintering

ʻO ka recrystallization ʻāpana SiC e hana ana i ka ʻōnaehana pūnaewele 3D

.

4. Hoʻonui i ka ʻili

ʻO ka uhi anti-oxidation → 3 × hoʻomaikaʻi i ka pale ʻana i ka corrosion

.

5.ʻO ka nānā ʻana i ka maikaʻi

Helu hoʻopaʻa inoa kūʻokoʻa no ka hiki ʻana o ke ola holoʻokoʻa

.

6.Hoʻopili palekana

ʻO ka papa haʻihaʻi haʻihaʻi + ʻaʻa wai + ka pahu hoʻoikaika ʻia

.

HOOLAHA HANA

Puhi Hooheehe Gas

Uhi Hooheehe Induction

Ke kapuahi hehee pale

No ke aha e koho ai iā mākou

FAQ

Q1: He aha nā mea maikaʻi o ka graphite crucibles silicon carbide i hoʻohālikelike ʻia me nā crucibles graphite kuʻuna?

✅ʻOi aku ke kūpaʻa wela: Hiki ke kū i ka 1800 ° C lōʻihi a me 2200 ° C no ka wā pōkole (vs. ≤1600 ° C no ka graphite).

✅ʻOi aku ka lōʻihi o ke ola ʻana: 5x ʻoi aku ka maikaʻi o ke kūpaʻa haʻalulu wela, 3-5x ʻoi aku ka lōʻihi o ke ola lawelawe.

✅Hoʻohaumia Zero: ʻAʻohe komo kalapona, e hōʻoiaʻiʻo ana i ka maʻemaʻe metala hoʻoheheʻe.

Q2: ʻO wai nā metala hiki ke hoʻoheheʻe ʻia i kēia mau crucibles?

▸Metala maʻamau: Aluminum, keleawe, zinc, gula, kala, etc.

▸Nā Metala Hoʻoikaika: Lithium, sodium, calcium (koi i ka uhi Si₃N₄).

▸Nā Metala Pahu: Tungsten, molybdenum, titanium (koi i ke kinoea māmā/inert).

Q3: Pono nā crucibles hou i ka mālama mua ʻana ma mua o ka hoʻohana ʻana?

Pono ʻia ka ʻai ʻana: E wela mālie i ka 300°C → paʻa no 2 mau hola (wehe i ke koena o ka wai).

Olelo Hoohehee Mua: E hoʻoheheʻe mua i kahi ʻāpana ʻōpala (e hana i kahi papa pale).

Q4: Pehea e pale ai i ka crucible cracking?

Mai hoʻouka i ka mea anuanu i loko o kahi kīʻaha wela (max ΔT <400°C).

Ka helu hoʻoluʻu ma hope o ka hoʻoheheʻe ʻana <200°C / hola.

E hoʻohana i nā ʻōpala crucible i hoʻolaʻa ʻia (e pale i ka hopena mechanical).

Q5: Pehea e pale aku ai i ka haki ʻana o ka crucible?

Mai hoʻouka i ka mea anuanu i loko o kahi kīʻaha wela (max ΔT <400°C).

Ka helu hoʻoluʻu ma hope o ka hoʻoheheʻe ʻana <200°C / hola.

E hoʻohana i nā ʻōpala crucible i hoʻolaʻa ʻia (e pale i ka hopena mechanical).

Q6: He aha ka helu kauoha liʻiliʻi (MOQ)?

Nā Hoʻohālike Maʻamau: 1 ʻāpana (loaʻa nā laʻana).

Nā Hoʻolālā Kuʻuna: 10 mau ʻāpana (pono CAD kiʻi).

Q7: He aha ka manawa alakaʻi?

⏳Nā mea waiwai i loko: Nā moku i loko o 48 hola.

⏳Nā Kauoha Kuʻuna: 15-25lāno ka hana ʻana a me 20 mau lā no ka ʻōpala.

Q8: Pehea e hoʻoholo ai inā ua hāʻule ka crucible?

Nā māwae > 5mm ma ka paia o loko.

Ka hohonu komo metala > 2mm.

Deformation > 3% (ana ana i ke anawaena o waho).

Q9: Hāʻawi ʻoe i ke alakaʻi ʻana i ke kaʻina hoʻoheheʻe?

ʻO nā pihi hoʻomehana no nā metala like ʻole.

Helu helu holo kinoea.

Nā kumu aʻo wikiō wehe ʻana i ka slag.